Crafting umbrella frames is a fascinating blend of art and engineering, essential for creating sturdy, reliable companions for rainy days. The frame of an umbrella is the backbone of its functionality, providing the structure that supports the canopy and keeps you dry. Let’s take a closer look at the construction of umbrella frames.

Materials:

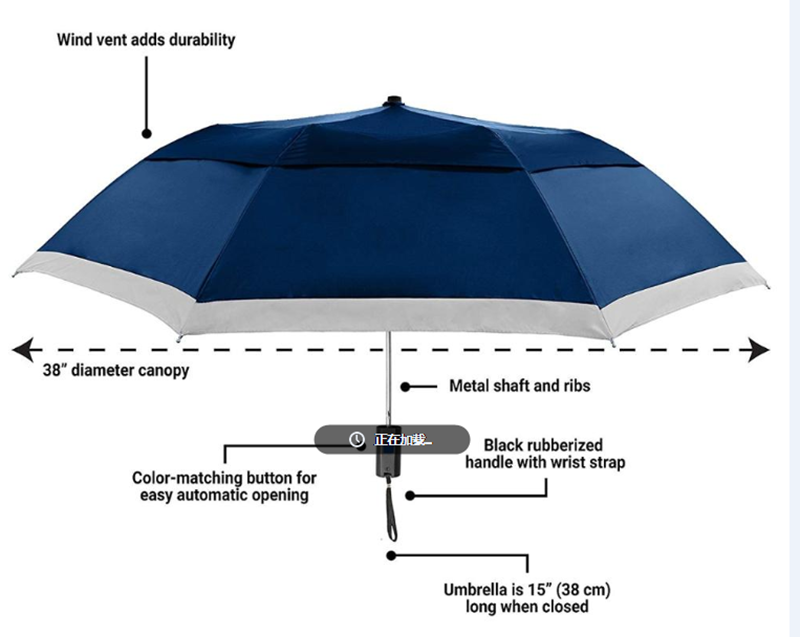

Ribs: The ribs are the most crucial part of an umbrella’s frame. They are typically made of materials like steel, fiberglass, or aluminum. Steel is strong but heavy, while fiberglass and aluminum are lighter but still durable.

Shaft: The shaft is the central support structure of the umbrella. It connects the handle to the canopy and can also be made of materials like steel or aluminum. Some high-end umbrellas use carbon fiber for a combination of strength and lightweight.

Joints and Hinges: These are the pivot points that allow the umbrella to open and close. They are often made of a combination of metal and plastic to provide strength and flexibility. Double-reinforced joints are common in quality umbrellas for added durability.

Construction Process:

Rib Assembly: Umbrella ribs are carefully constructed to provide strength while allowing flexibility. They are attached to the shaft using joints and hinges, forming a skeleton for the canopy. The number of ribs can vary, with most umbrellas having 6 to 8.

Shaft Attachment: The shaft is attached to the top of the rib assembly. It runs through the center of the umbrella and connects to the handle at the bottom. Proper alignment and attachment are crucial to ensure the umbrella opens and closes smoothly.

Post time: Sep-11-2023